What is circular economy?

“In the end, the term ‘circularity’ may just be one way to make us aware that we need a more encompassing, integrated and restorative sustainability path that includes people as much as technology and nature.”

Michiel Schwarz, A Sustainist Lexicon, 2016

In recent years, a new paradigm has taken over the sustainability discussion. Circular economy is the buzzword appearing in government reports, company policies, and Twitter hashtags. But what is circular economy and why does it matter to businesses and individuals worldwide?

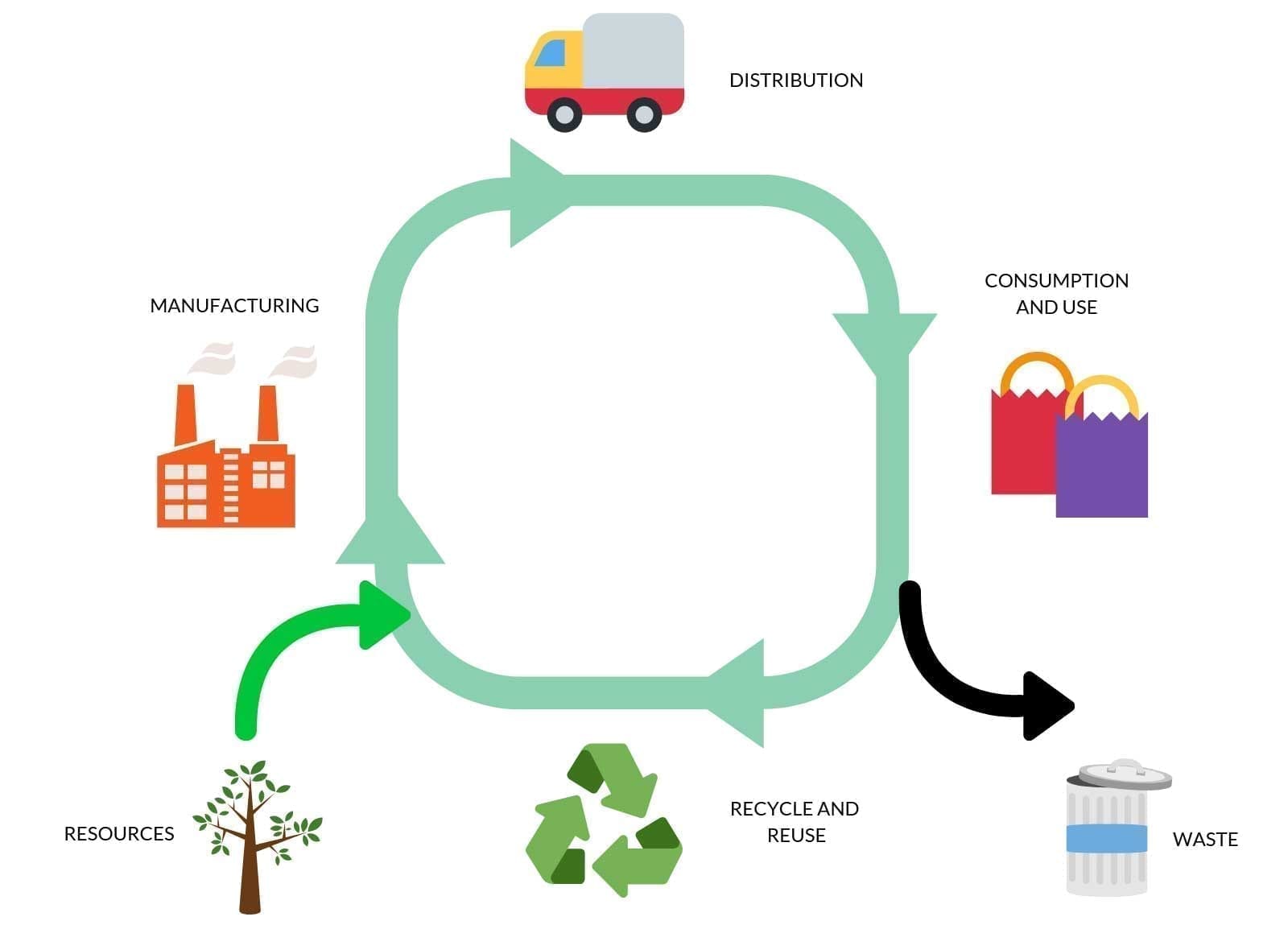

Circular economy is an economic model based on implementing the so-called three Rs: Reduce, Reuse, and Recycle. It is based on the acknowledgment that we cannot continue to waste the world’s resources as we have done until now and focuses on supporting environmental and social sustainability.

Kircherr et al. (2017) define Circular Economy as “an economic system that is based on business models which replace the ‘end-of-life’ concept with reducing, alternatively reusing, [and] recycling […] materials in production/distribution and consumption processes, […], with the aim to accomplish sustainable development, which implies creating environmental quality, economic prosperity and social equity, to the benefit of current and future generations[1]”(1).

Did you know that ¼ of the world’s population consumes more than 3/4 of natural resources?

As our rate of consumption of natural resources accelerates instead of slowing down[2], it is necessary to tackle the manufacturing and distribution of goods in a more sustainable way. Moreover, consumers are becoming more and more aware of the impact of resource waste, harmful chemicals, and unethical labor practices.

Doing the right thing is a good move both from an ecological and financial standpoint: you can minimize pollution and preserve natural resources, while also making sustainability a competitive advantage.

Thus, what are the benefits and challenges of applying the circular economy paradigm to your supply chain? How do they relate to inventory management?

Why you need inventory accuracy to deploy a circular supply chain

First of all, whether you manufacture goods or supply them to other businesses, you likely struggle with inventory accuracy.

In order for a business to be circular, it is essential to know where each item is at any moment in time. Inventory accuracy and circular economy are complementary: without one there cannot be the other. If you don’t know where each item in your stock is, you cannot implement lifecycle sustainability.

You will experience overstock and out of stock, which result in less efficient use of storage space, excessive use of transportation, and cause resource waste in addition to a less effective sales cycle.

If you tracked every item in your inventory, you could:

- Avoid situations where you don’t know what you have in stock and risk not being able to respond to customer requests in a timely manner to close the sale.

- Optimize your logistics. Transport goods based on actual need, and reduce your business’ carbon footprint.

- Have a complete overview of the lifecycle of your products, enabling you to avoid waste and surplus. For example, you could replenish right on time or receive an alert when an item in your stock is approaching the scheduled end of life and needs to be replaced.

- Eliminate expensive surprises. If you have a big stock that moves quickly and is updated with new items fairly often, you might discover at the end of the fiscal year that you have a huge quantity of items you don’t know the location of and be forced to record huge losses, affecting your projected profits.

- Implement and support Green Supply Chain Management Practises. GSCM addresses environmental sustainability and wants to reduce waste, carbon emissions, and energy use through the whole supply chain. Implementing Green Supply Chain Management has been proved to improve both operational and environmental performance.

In conclusion, to promote reuse and recycling of resources and limit waste, inventory accuracy is a must.

Without inventory accuracy, you cannot transform your supply chain to avoid waste

Moreover, you risk expensive surplus and out of stock situations. In fact, circular asset management is a way to cut losses and establish a more transparent supply chain.

As circularity becomes a requirement, the importance of real-time item tracking and inventory efficiency is made even clearer. Companies have started to reintegrate in their supply chain old items customers can return or offer refills and repairs to lengthen their products’ lifecycle.

When moving towards a circular supply chain, it is necessary to also implement inventory accuracy, to make sure no waste occurs. Inventory accuracy could also support initiatives telling customers how much of their old items had been reused in new products. Furthermore, it could provide exact measures of companies’ environmental efforts and compliance with sustainability regulations.

If you know where each of your items is, you can deploy a green supply chain that is more than shallow eco-washing. You can guarantee to your stakeholders, partners, staff, and customers that you are doing all that’s possible to contribute to a more sustainable world.

How to achieve real-time inventory accuracy

Real-time inventory accuracy is possible with the use of RFID technology. RFID or Radio-frequency identification allows each item to become traceable anywhere, in real-time. With RFID, 100% inventory accuracy is possible. This means you would never lose track of your stock and you would be able to trace each item during its lifecycle.

How does this work? If you implement RFID, each product has a small tag that can be read at a distance thanks to radio frequency. Differently from barcode, you can scan several items simultaneously and in a wider range.

This results in much faster and more accurate results. If you can scan your whole inventory in just a couple of hours instead of days or even weeks, you are able to perform inventory count more frequently and have real-time information about which items are selling well and which aren’t.

Frequent inventory counts also decrease mistakes and lost items. If you only perform annual or bi-annual inventory takes, you might have thousands of items missing and have no idea where they are and whether they are lost forever. Frequent inventory takes also helps you reduce inaccuracies in your item counting operations.

In fact, RFID reduces the potential for lost items and human error, as employees don’t have to scan items individually anymore.

Moreover, by speeding up and automating inventory management, your employees have also time to focus on what really matters: customers and their needs. Imagine, for example, a shop where employees can immediately tell customers whether the item they want is available in their preferred size and color and find its exact position on the shelves.

Inventory accuracy can also help you optimize your sales strategy

If you know exactly which items are where and when they leave the store, you can easily optimize your stock across multiple stores. For example, you can move items based on what sells best in different locations and, if you have control of your whole supply chain, only produce what’s in demand.

The business case of RFID in this context was emphasized by one of the biggest retail operators on the market, Zara, which widely adopted RFID in 2014. Real-time inventory management and asset tracking were reported as two of the biggest benefits. In fact, RFID adoption allowed for easy restocking of items and a complete overview of best-selling styles. Employees can easily locate items customers are looking for, and replenish items as they get sold, avoiding the risk of customers not finding what they want.

“It gives us great visibility, knowing exactly where each garment is located. It really changes how we operate our stores.”

Pablo Isla, CEO, Indetex

So, while RFID is the best solution to achieve real-time inventory accuracy and guarantee seamless inventory management, it has also the potential to improve the customer experience and boost sales.

Curious about learning more? We have tackled this topic more in-depth in our blog post 5 Ways that RFID and Automated Real-Time Inventories Dramatically Cut Costs for Retailers and our brand-new ebook 5 reasons your company manages its inventory inefficiently and how to fix it.

the potential of RFID in the circular supply chain is not limited to inventory accuracy

For example, Martin Stuchtey, global leader in McKinsey’s Sustainability & Resource Productivity Practice, emphasized the role of RFID to identify materials and ensure the transparency of material flows in “Questions and answers on the circular economy” (2013).

RFID can support transparency in the supply chain and ensure that everything is trackable, visible, and easy to identify in each lifecycle stage.

As we run out of time to act on the ongoing climate crisis and more and more businesses pledge their commitment to sustainability and a transparent supply chain, the role of RFID will only grow.

In fact, 69% of retailers around the world have reported adopting RFID at a significant rate and the rate of adoption has been steadily growing over the past years (3).

Want to understand whether your business could benefit from implementing RFID? Book a demo with one of our RFID specialists to learn more.

Circular Economy Infographic

Download our infographic or continue learning about the potential of RFID for sustainability.

Sources

[1](1) Kirchherr, J., Piscicelli, L., Bour, R., Kostense-Smit, E., Muller, J., Huibrechtse-Truijens, A., Hekkert, M., 2018. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecological Economics 150, 264–272.

[2](2) IRP (2017). Assessing global resource use: A systems approach to resource efficiency and pollution reduction. Bringezu, S., Ramaswami, A., Schandl, H., O’Brien, M., Pelton, R., Acquatella, J., Ayuk, E., Chiu, A.,Flanegin, R., Fry, J., Giljum, S., Hashimoto, S., Hellweg, S., Hosking, K., Hu, Y., Lenzen, M., Lieber, M., Lutter, S., Miatto, A., Singh Nagpure, A., Obersteiner, M., van Oers, L., Pfister, S., Pichler, P., Russell, A., Spini, L., Tanikawa, H., van der Voet, E., Weisz, H., West, J., Wiijkman, A., Zhu, B., Zivy, R. A Report of the International Resource Panel. United Nations Environment Programme. Nairobi, Kenya.

(3) Accenture Strategy, Transforming Modern Retail, 2018.